With a focus on addressing water shortage and storage The Crisis Kitchen was our response to creating a mobile kitchen.

Above: As see in the Annual Student Show!

Above: As see in the Annual Student Show! Above: As shown, a funnel, a filter to remove particles, and a bucket for fetching water.

Above: As shown, a funnel, a filter to remove particles, and a bucket for fetching water. Above: how a disaster victim carries the pack. Below: valves to release the water stowed.

Above: how a disaster victim carries the pack. Below: valves to release the water stowed. The walls for the unit act as water bladders and can store up to 3.5 liters. The average person requires 1.5 to 2 liters a day to survive. Additionally we divided up the lining into three separate bladders to increase survivability if one becomes punctured.

The walls for the unit act as water bladders and can store up to 3.5 liters. The average person requires 1.5 to 2 liters a day to survive. Additionally we divided up the lining into three separate bladders to increase survivability if one becomes punctured. Measuring and sewing the lining to the Crisis Kitchen.

Measuring and sewing the lining to the Crisis Kitchen.

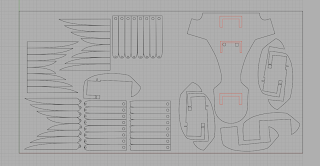

Part of our second prototype model.

Part of our second prototype model. Sewing our walls.

Sewing our walls. Let the assembly begin!

Let the assembly begin! Here is were we sketched ideas out as a group before making the prototype.

Here is were we sketched ideas out as a group before making the prototype.

Uh oh! How do you carry it?

Our initial concept of a mobile kitchen.

Our initial concept of a mobile kitchen.